Process overview

2. Laminating and Coating Hydrophobic Film

| ID | 2.1. | |

| Title | Preparing PDMS adhesive | |

| Scope | Prepare PDMS as adhesive for dielectric film | |

Materials

- DC 184, CH DE – Silicone Elastomer Kit, 1.1kg, Dow Corning

- Mixing beaker

- Micro-Balance

Step-by-step

- Add 10 gram of Part A (base) to beaker

- Add 1 gram of Part B (Curing agent) to beaker (ratio 1:10) (fig 1)

- Stir well using plastic spatula (fig 2)

- Put beaker into desiccator and put under vacuum for 2 minutes to degas (fig 3)

Pictures / Videos

fig 1

fig 2

fig 3

Files / Templates:

| ID | 2.2. | |

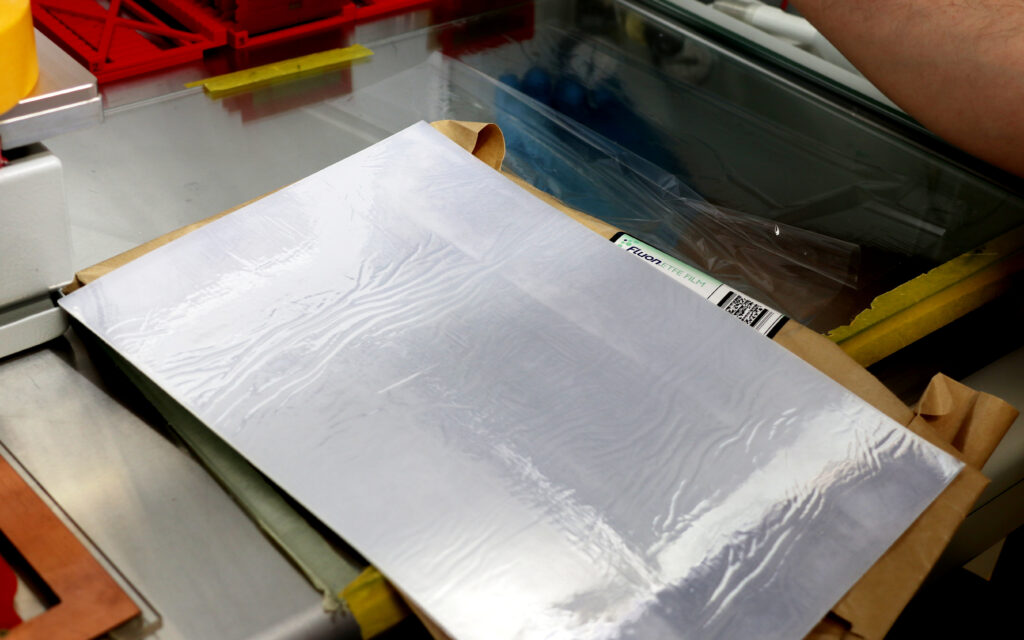

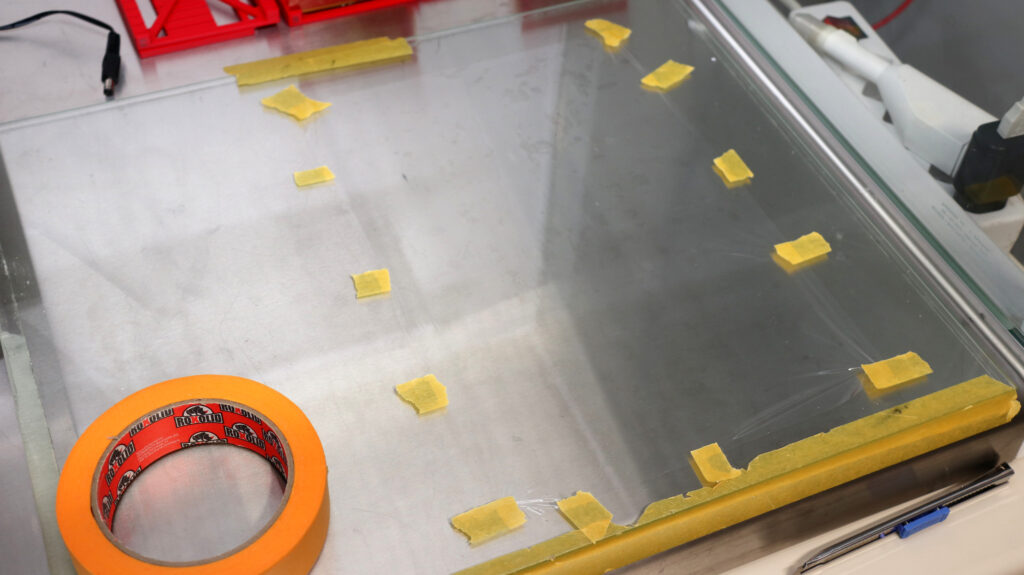

| Title | Stretching dielectric film | |

| Scope | Prepare dielectric film (ETFE) by stretching it flat | |

Materials

- AGC Fluon ETFE Film, 12 um, with corona treatment

- Masking tape

Step-by-step

- Carefully remove one layer of ETFE film from package and lay down flat (on glass surface) with corona treated side facing up (fig 1)

- Stretch film evenly by attaching it to surface using masking tape (fig 2)

Pictures / Videos

Files / Templates:

| ID | 2.3. | |

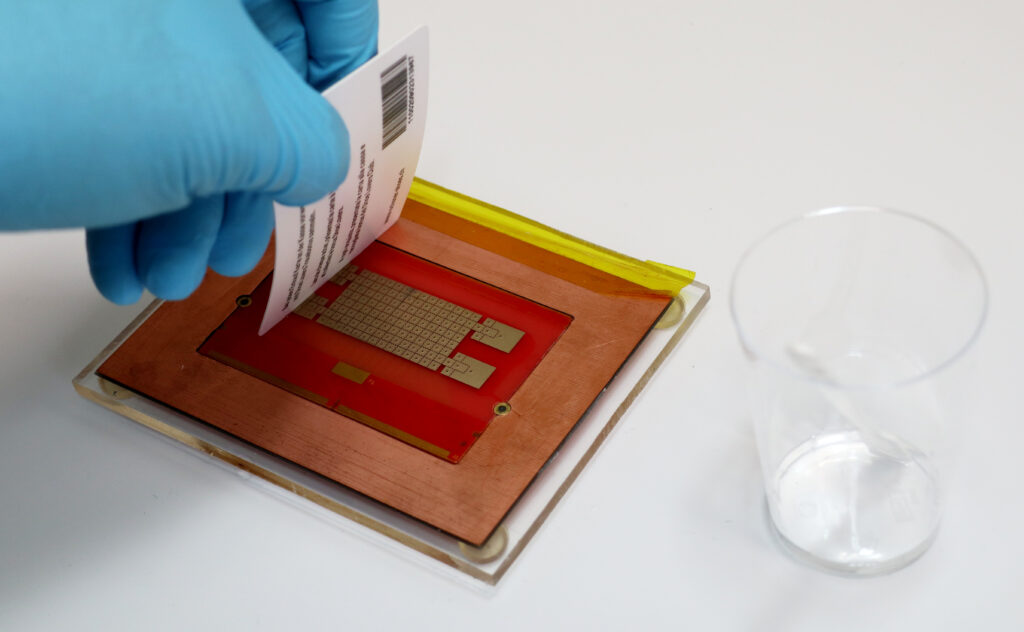

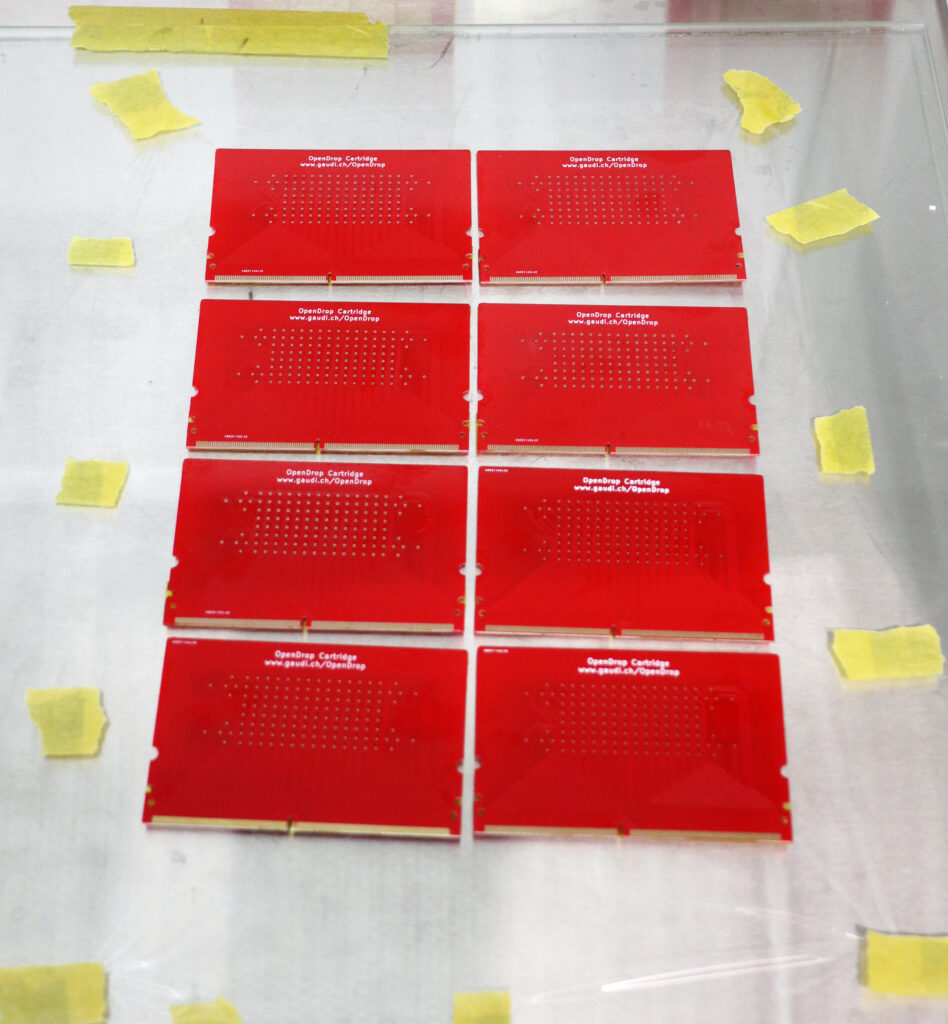

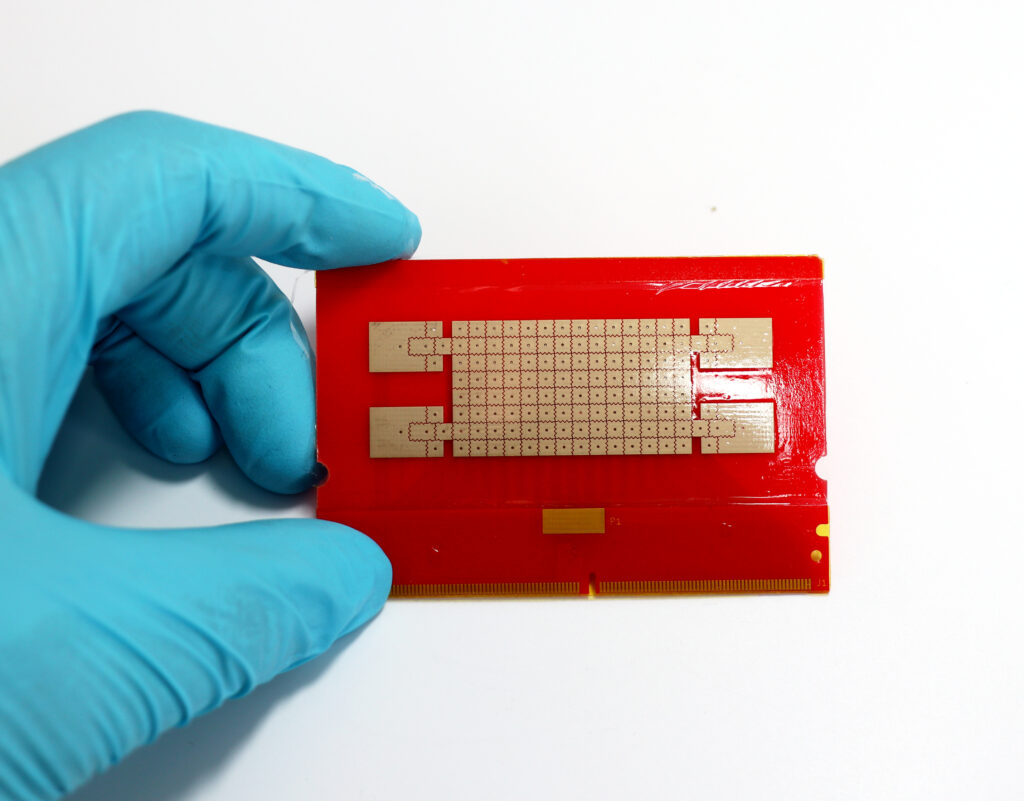

| Title | Priming Electrode boards | |

| Scope | Apply priming to masked electrode boards and protect with tape | |

Materials

- Electrode board with makings applied

- DOW CORNING® 1200 OS Primer

(Primer for silicone elastomers, silicone foams and adhesives/sealants)

Step-by-step

- Measure 5 ml of primer into buffer container (always use buffer container to prevent contamination and product deactivation)

- Apply one coat of primer to electrode board using a lint free paper towel (fig 1)

- Allow allowed to air dry for 15 minutes

- Protect the surface by applying a masking tape over it (fig 2).

Laminate electrode board soon after priming (< 6 hours)

Pictures / Videos

fig 1

fig 2

Files / Templates:

| ID | 2.4. | |

| Title | Laminating dielectric foil with PDMS | |

| Scope | Apply PDMS adhesive to electrode board and laminating ETFE foil | |

| Buy | Shop link for Laminated and Coated Electrode Board |

Materials

- Electrode board with makings and priming

- Mixed PDMS adhesive

- Stretched ETFE foil

Step-by-step

- Remove protective masking tape from electrode board

- Apply a small amount of PDMS adhesive directly to the electrode array

- Spread the adhesive evenly using a squeegee.

- Remove all excess adhesive in a second pass with the squeegee. There should be as little adhesive on the surface as possible (just impregnated)

- Remove liners from top and bottom masking lines

- Apply electrode board to stretched ETFE film. Be careful when putting it down to not move and introduce wrinkles. Press down.

- Clean backside of electrode board from any excessive adhesive

- Cut out ETFE film around the electrode board to release it from the sheet.

- Wrap electrode baord with film applied to it into a folded piece of paper

- Pass the board wrapped in paper through a laminator (Laminator type: TCM, Temperature: 130°C)

- Let the PDMS adhesive dry for 12 hours (covered with aluminum foil to prevent dust and charges)

Pictures / Videos

Files / Templates:

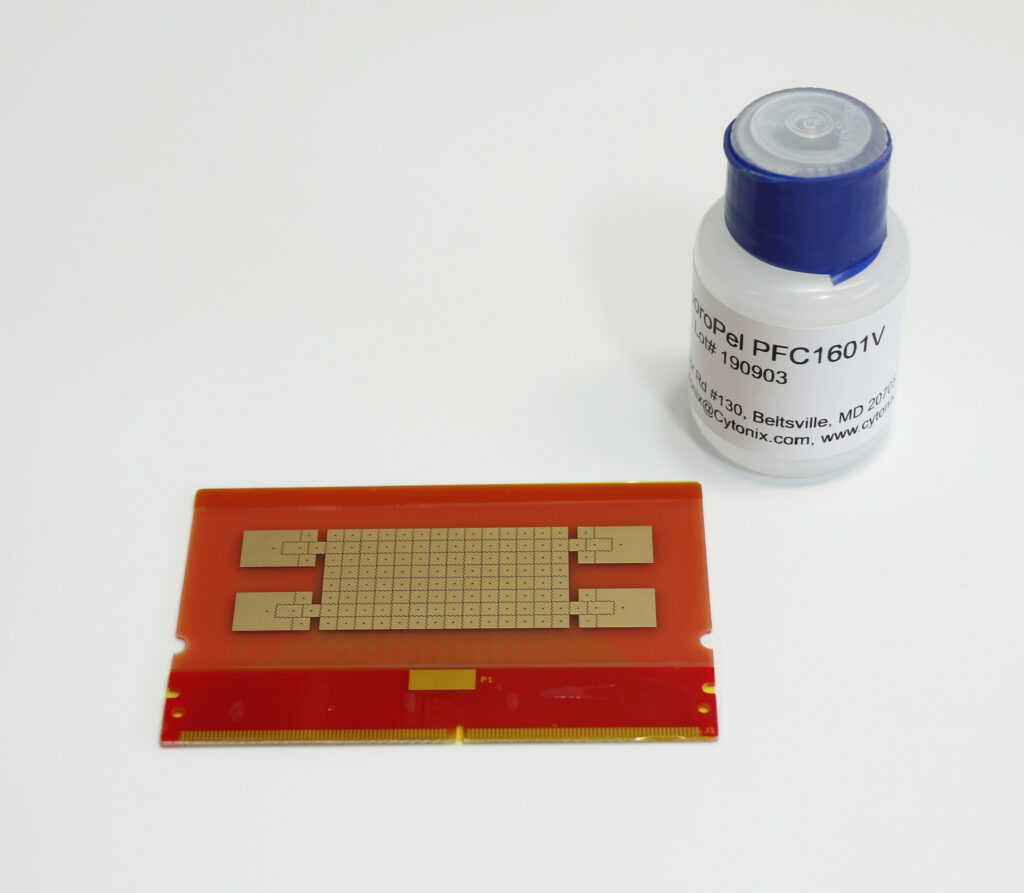

| ID | 2.5. | |

| Title | Coating film on electrode board | |

| Scope | Applying a hydrophobic coating to the film on the electrode board | |

| Buy | Shop link for Laminated and Coated Electrode Board |

Materials

- Electrode board with laminated film

- Hydrophobic coating material (FluoroPel PFC1601V)

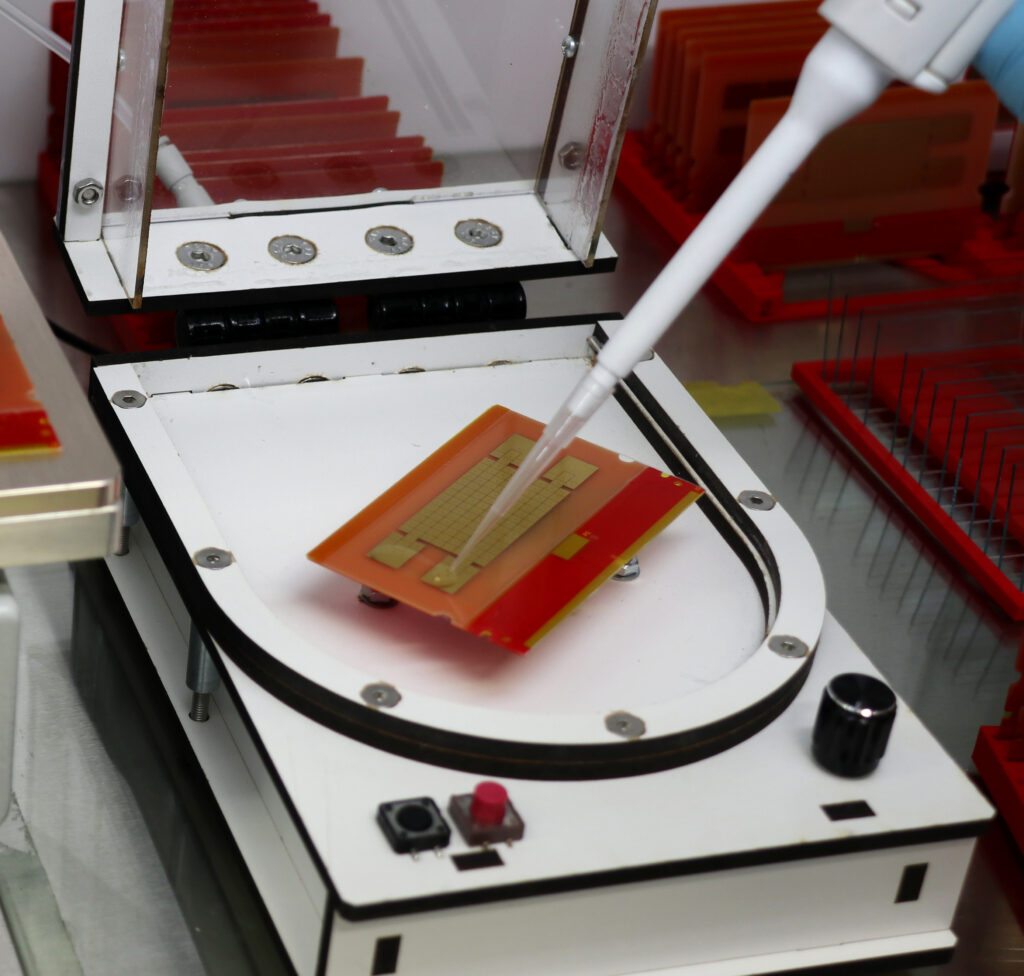

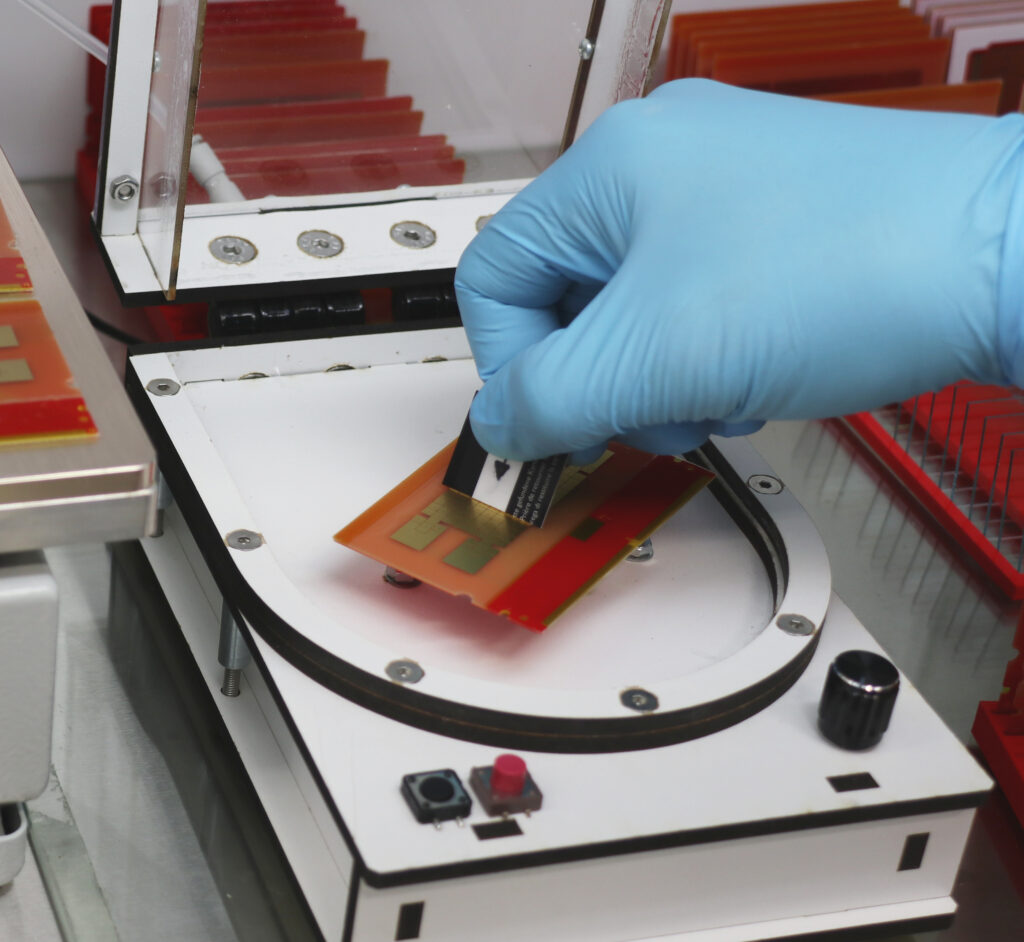

Step-by-step

- Put the electrode board on a spin-coater with vaccum chuck

- Apply 60 ul of FluoroPel onto the film on one edge of the board (fig 1)

- Spread the coating evenly over the whole surface of the electrode array using a plastic squeegee (fig 2)

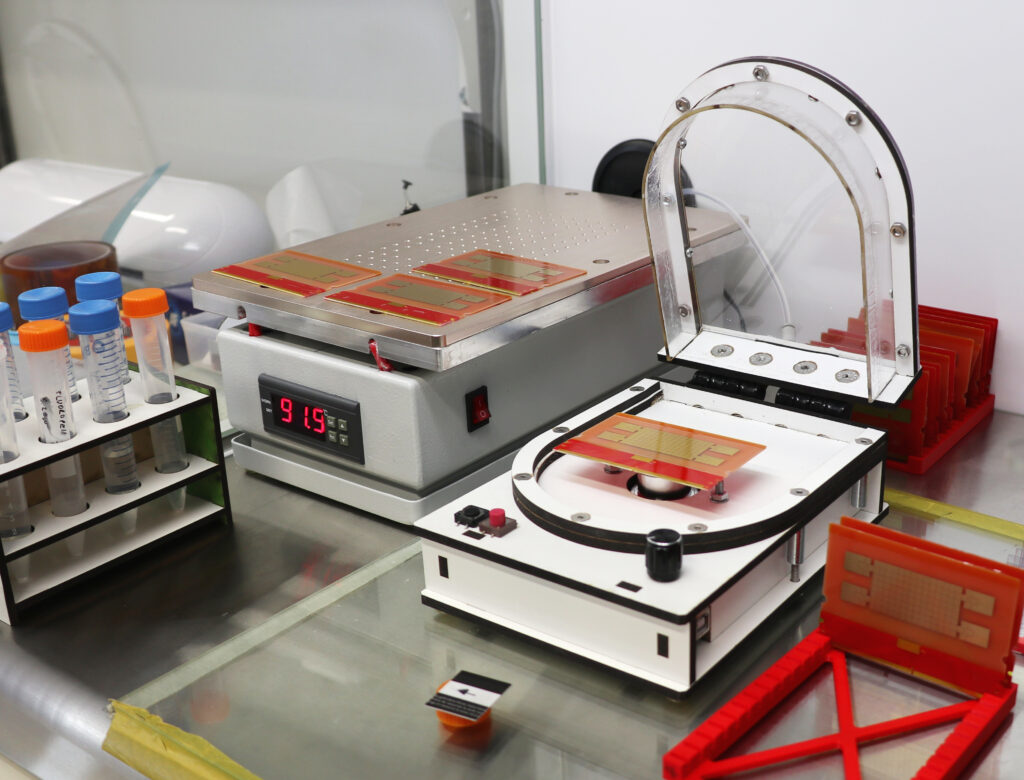

- Spin at 2500 rpm for 30 seconds (fig 3)

- Cure on hot plate at 90°C for 20 minutes (fig 4)

- Store in board rack for further use

Pictures / Videos

fig 1

fig 2

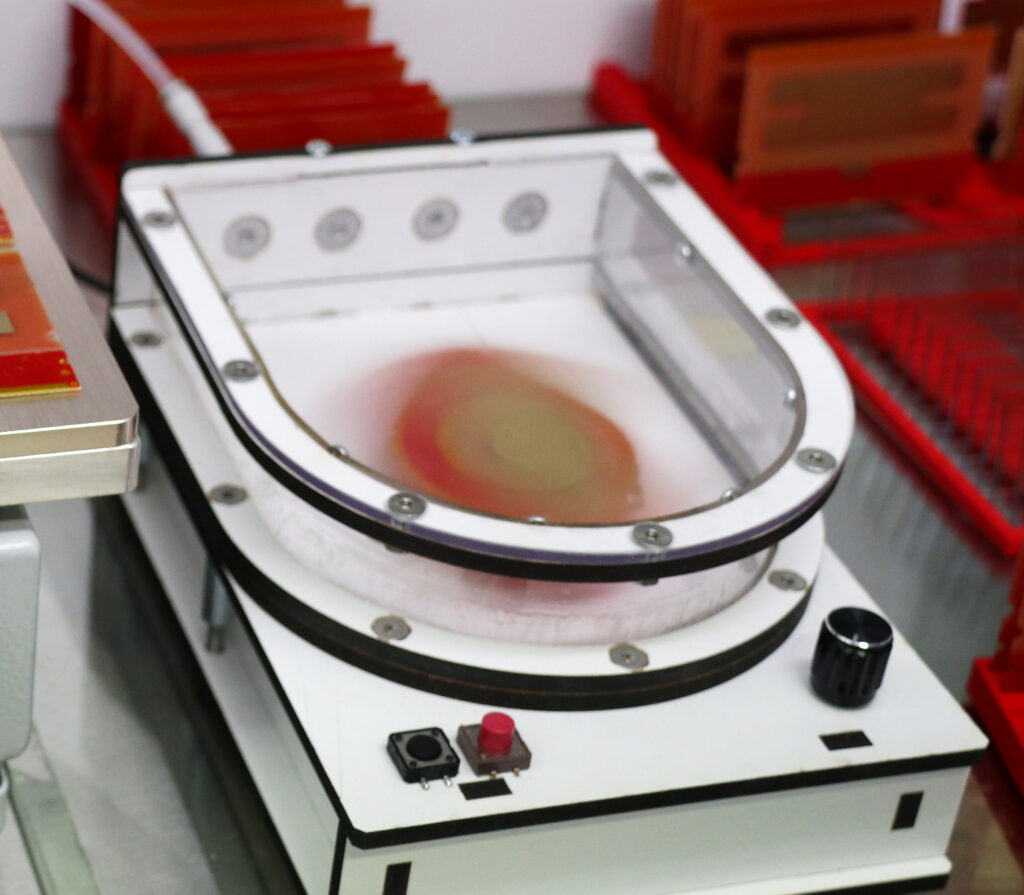

fig 3

fig 4

Files / Templates: